UV-C LED Benefits

Enables a lower risk disinfection alternative

Although UV disinfection is generally considered safer than chemical disinfection, all conventional UV lamps typically use between 5-200 mg of mercury per lamp. These UV lamps require routine replacement and are susceptible to breakage during transportation, handling, and operation. UV LEDs are mercury-free and provide a safer alternative. This has created new markets for UV disinfection where traditional UV lamps containing mercury were banned for safety reasons (e.g. medical devices, space).

Conventional UV lamps hold their mercury either in a liquid form (more common in medium pressure lamps) or an amalgam (more common in low pressure, high output lamps). Amalgam UV lamps contain solid “spots” which consist of an alloy of mercury and another element, such as indium or gallium. Liquid mercury lamps have the potential to be hazardous both during operation and when the lamp is off. While the lamp is operating the mercury vaporizes; if the lamp is broken, mercury vapor is easily dissolved into the treated product. Accidents and improper procedures increase the risk of exposure to people and the local environment.

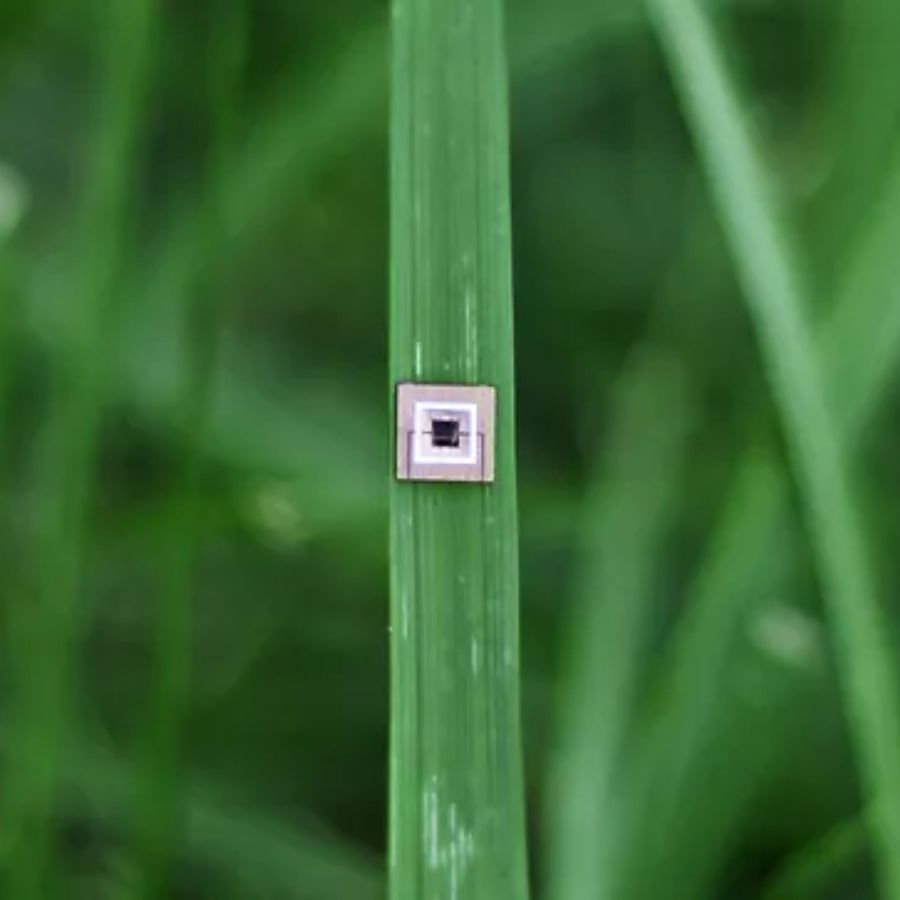

UV-C LEDs do contain small amounts of elements such as the metals gallium and magnesium and the metalloids silicon and boron (although boron is not predominantly used). These metals and or metalloids are bound within a stable crystal structure and cannot leach into the environment.

The inherent stable crystal structure of an LED ensures that UV-C LEDs are very robust to mechanical or environmental shock.