UV-C LED Benefits

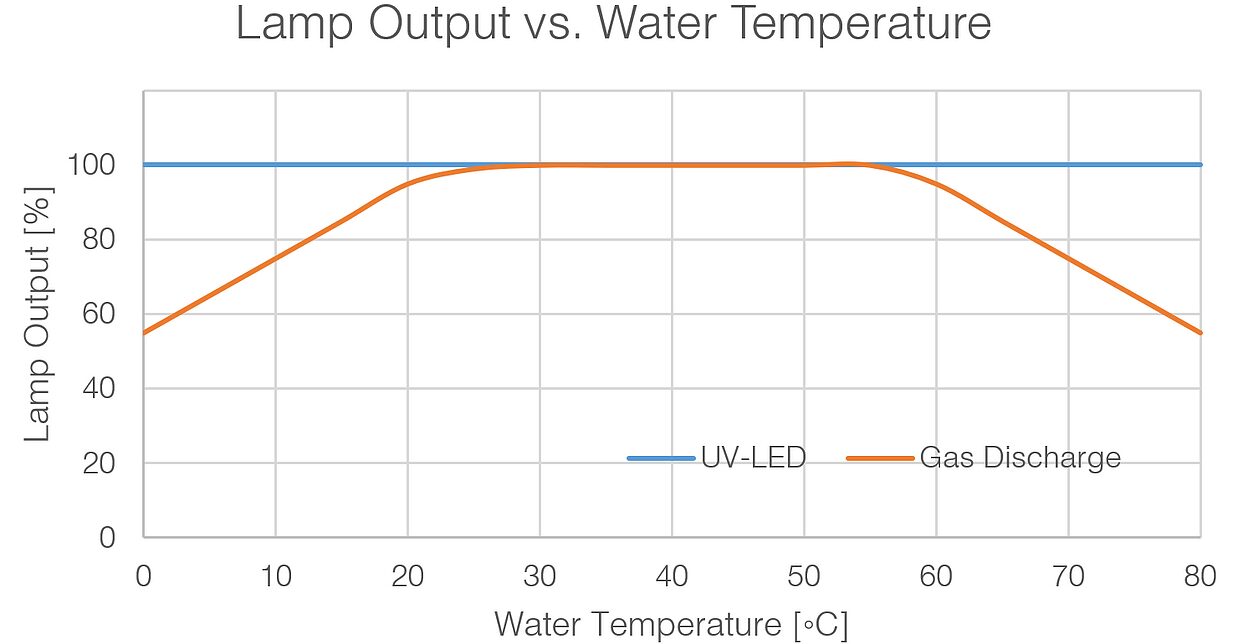

Enables more temperature control over process water and constant UV output regardless of temperature

Conventional UV lamps produce a substantial amount of heat which is then transferred to the flow of the water. This leads to the heating of the process water and elevated heat can lead to quartz sleeve fouling. Also, conventional UV lamps are far more temperature sensitive making them less effective in non-ideal circumstances.

UV LED systems can be engineered to not transfer heat into the water, thus reducing fouling rates and ensuring the constant UV output regardless of the water temperature.

One of the key benefits of LED-based systems is that they do not transfer heat into the water. LEDs emit all their light at the front surface of the device and heat at the back surface, whereas mercury lamps emit both light and heat through the same surface.

UV-C LEDs emit more heat than mercury-based lamps, which must in turn be managed correctly. This can be done through a variety of ways and will aid in the longevity of the system. Implementing thermal heat-reduction techniques and heat monitoring is key to sustaining long-lasting UV LEDs.

Quartz sleeve fouling has been long identified as a significant challenge in the application of UV disinfection. Fouling reduces the amount of light available for disinfection. Many factors contribute to fouling including elevated water temperatures caused by the process water heating up during low flow events. Conventional UV systems have attempted to reduce fouling by routinely purging hot water during no-flow events, implementing mechanical cleaning mechanisms, and recently, have introduced a dimming feature to reduce water temperatures. All measures add cost and complexity. By comparison, UV LEDs can be engineered not to transfer heat into the water and can be switch off during no-flow events. Reducing water temperature is a proven method to reduce quartz sleeve fouling.

Fluctuations in water temperature will impact a conventional UV lamp’s output and will, therefore, impact a UV disinfection system’s ability to achieve the required UV dose. Each UV lamp type is affected differently with standard low pressure (LP) and low-pressure high output (LPHO) UV lamps being the most sensitive to temperature changes. UV-C LEDs are less impacted by temperature variations ensuring a constant UV output regardless of water temperature.